Marlowe Moncur, the technology director of aircraft window manufacturer GNK Aerospace explained the purpose of the “breather hole” to io9. It’s a hole designed to balance out the pressure between the last two layers -yes, there are a few layers – of a typical pressurized-cabin window.

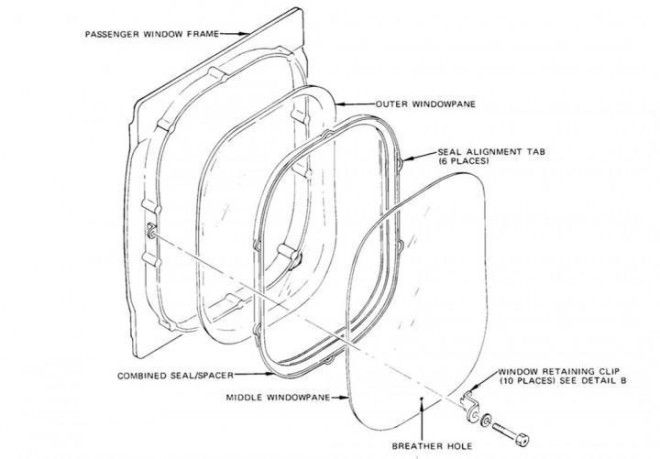

Before we go any further into the purpose of the “breather hole“, we will first check out how a window in a pressurized passenger cabin

is set up. As shown in the Boeing 737 maintenance manual (the most widely produced jet airliner in aviation history), the window structure

consists of three layers of acrylic – a tough, transparent and flexible resin – although only two of them have an actual structural function.

These structural layers are the intermediate and outer ones – while the inner layer (called “scratch pane”) only serves as a buffer between

the passengers and the structure of the window itself. These layers prevent the cabin from reaching the external pressures that, depending

on altitude, are too low for the vital functions of the human body.

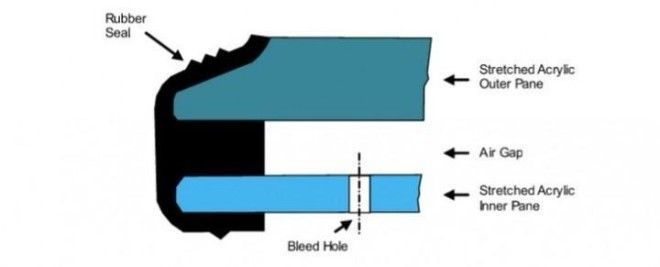

Basically, the primary structural window garantees the cabin remains at a constant pressure equivalent to an altitude of 7,000 feet, which is still quite acceptable for the body. However, in most cases, only the last acrylic layer is responsible for ensuring such conditions; the intermediate layer is just there for extra safety. Having said that, let us get back to the misterious little hole.

As can be noted in the diagram shown above, the breather hole is located in the middle layer of the window. This little puncture acts as a

bleed valve ensuring that the pressure between the last two layers and the cabin always remains the same. This is necessary as a way of preserving the middle layer (the extra safety one) so it is only exposed to severe pressure differences in cases of emergency – that is, if the last layer the window is fractured in some way.

However, the effective use of this security layer is incredibly rare. As Moncur explained, all windows are exposed to rigorous testing before

receiving the seal of approval.

Furthermore, any possible cracks in the outermost layer of the window is enough to justify an emergency landing – even if the middle layer is fully capable, in principle, to maintain the appropriate cabin pressure conditions. Better safe than sorry, right?

Finally, Moncur also clarifies that the breather hole also serves to preventfreezing and fogging between the outer layers of the window. Of course, that doesn’t always work since it is not rare to find photographs showing some frost on the windows.