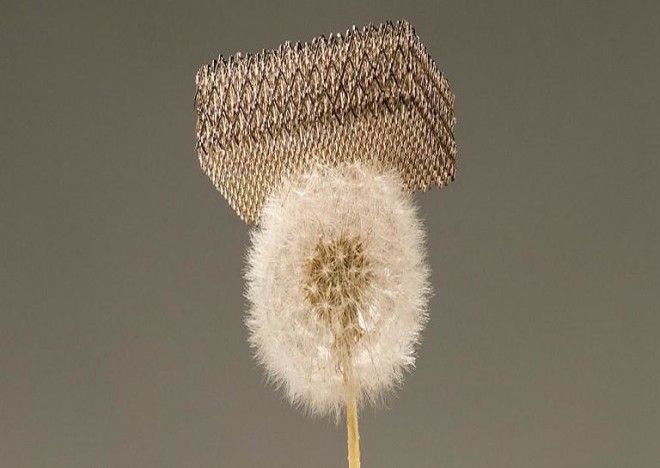

Structure of the microlattice

The microlattice is a 3D open-cellular polymer structure. The latices in the structure of the metal are made up of interconnected hollow metal tubes. The metal is very rigid despite the fact that the wall thickness of the hollow tubes is just 100 nanometers, that is 1000 times thinner than human hair.

What is interesting about this design is the inspiration behind it. Boeing was fascinated by the nature of human bones. Human bones are very rigid on the outside but almost completely hollow on the inside. This nature not only makes the bone very difficult to break due to its rigidity, but it also means that the bone is light enough to be supported by the human body.

Possible applications of the microlattice

“One of the main applications that we’ve been looking into is structural components in aerospace,” said Sophia Yang, who is a Research Scientist of Architected Materials at HRL Laboratories. HRL Laboratories worked together with Boeing on the microlattice project.

“The trick is to fabricate a lattice of interconnected hollow tubes with a wall thickness of 100 nanometers, 1,000 times thinner than a human hair,” according to Dr. Tobias Schaedler from HRL Laboratories.

Advertising

One other interesting property of the microlattice that can be exploited is this; due to its cellular architecture, the metal has some incredible mechanical properties. These properties include compression recovery from strains that exceed 50% and a very high energy absorption. It is quite breathtaking for a metal to exhibit such properties.

HRL says that the metal could be used inside an aircraft, in places such as seat frames, walls and flooring. The use of such a light metal in an aircraft means that the aircraft will consume less fuel due to the decrease in weight. This will result in reduced cost of operation.

HRL is also working on using the technology with NASA on future spacecraft designs. DARPA on the other hand is interested in using the metal for energy damping.